Diesel engines, such as the 6.7 Powerstroke commonly found in Ford trucks, have gained immense popularity due to their durability and high torque output. However, like any mechanical component, these engines are not immune to issues. One critical component prone to failure is the CP4 fuel injection pump. The CP4 (Common Rail Pump 4) is an integral part of the modern diesel engine’s fuel delivery system. When this vital component fails, it can lead to a cascade of problems affecting the engine’s performance and reliability. In this article, we’ll delve into the symptoms of a failing CP4 on a 6.7 Powerstroke engine, as well as provide some insights into potential causes and solutions.

Understanding the CP4 Fuel Injection Pump

When it comes to the intricacies of modern engine technology, the CP4 fuel injection pump stands as a testament to engineering marvel. In the heart of a 6.7 Powerstroke engine, the CP4 pump plays a pivotal role, orchestrating the ballet of fuel delivery that powers your vehicle. As we embark on a journey to unravel the enigma of the CP4 pump and its associated symptoms, let’s take a moment to delve into its essence.

Role of the CP4 Fuel Injection Pump

Imagine your engine as a complex symphony, each cylinder a musician playing a crucial note. The CP4 pump takes on the role of the conductor, ensuring that the fuel, akin to musical notes, is delivered with meticulous precision to each cylinder at the exact moment it’s needed for the combustion masterpiece.

Key Differences

Let’s draw a table to highlight the distinctive features of the CP4 pump compared to its predecessor, the CP3 pump:

| Aspect | CP4 Fuel Injection Pump | CP3 Fuel Injection Pump |

|---|---|---|

| Lubrication | Relies on high-pressure fuel for internal lubrication | Self-lubricated |

| Precision | Delivers fuel with heightened precision to cylinders | Slightly less precise |

| Vulnerability | Prone to damage with poor fuel quality or contaminants | More resilient |

| Efficiency | Improved fuel atomization, enhancing combustion | Slightly lower efficiency |

Symptoms of a Failing CP4 on 6.7 Powerstroke

CP4 pump, a vital component that dances with fuel and combustion. This complex symphony can, unfortunately, turn into a discordant melody when the CP4 pump begins to falter. Let’s embark on a journey through the labyrinth of symptoms that signify a faltering CP4 pump’s presence:

Symptoms of CP4 Pump Distress

| Symptom | Manifestation | Consequence |

|---|---|---|

| Hard Starting | Extended cranking before ignition. | Struggle to attain optimal fuel pressure for combustion. |

| Rough Idling | Uneven engine performance; rough idling. | Inconsistent fuel delivery causing vibrations. |

| Loss of Power | Decreased power and acceleration. | Insufficient fuel supply hampers performance. |

| Engine Misfires | Sudden power loss, jerking while driving. | Disrupted fuel delivery affecting combustion. |

| Increased Exhaust Emissions | Higher emissions, potential check engine light. | Incomplete combustion due to fuel inefficiency. |

| Poor Fuel Efficiency | Reduced mileage for the same distance. | Incomplete combustion leading to higher fuel consumption. |

| Check Engine Light | Illuminated dashboard sentinel. | A potential hint at various underlying issues. |

| Metallic Contaminants | Release of metallic debris into the fuel system. | Fuel contamination and potential clogging. |

| Abnormal Noise | Unusual knocking or ticking from the engine. | Audible signs of internal pump damage. |

| Complete Engine Failure | Catastrophic engine damage due to debris circulation. | Engine breakdown demanding costly repairs. |

Hard Starting

Initiating the ignition becomes a prolonged endeavor, an impatient dance between your key and the engine’s reluctance. The CP4 pump, strained and weary, battles to muster the necessary high fuel pressure for optimal combustion. This ballet of elements struggles to culminate in a harmonious ignition.

Rough Idling

The heartbeat of your Powerstroke engine stutters, sending vibrations that course through its metal veins. Uneven engine performance becomes evident as the CP4 pump’s faltering fuel delivery results in cylinders firing at discordant intervals. What should be a seamless symphony transforms into a jittery rhythm.

Loss of Power

As you command the throttle, the response falters—a noticeable dip in power and acceleration. The fuel, a lifeline for engine prowess, falls short in reaching the cylinders. Whether towing Herculean loads or aiming for swift acceleration, the CP4 pump’s weakness emerges as a glaring Achilles’ heel.

Engine Misfires

A once fluid journey on the road is disrupted by sudden power vacuums, disconcerting jerks, and an unsettling cacophony. The CP4 pump’s struggles sow chaos in fuel delivery, causing combustion irregularities. Your engine’s orchestra loses synchronization, leading to a discordant performance.

Increased Exhaust Emissions

The invisible tendrils of inefficiency creep into the atmosphere, heralded by the telltale scent of unburned fuel. The CP4 pump’s inability to atomize fuel adequately results in higher levels of emissions. This environmental betrayal might even beckon the check engine light as an emissary of concern.

Poor Fuel Efficiency

The journey grows longer, the destination closer to becoming elusive. Incomplete combustion orchestrated by the faltering CP4 pump leads to heightened fuel consumption. The miles stretch, yet the fuel gauge drops disproportionately, a testament to combustion’s ineffable intricacies.

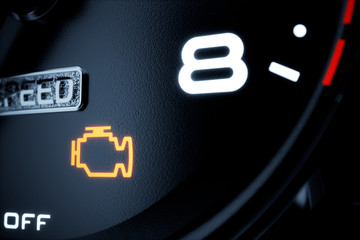

Check Engine Light

A sentinel awakens on your dashboard, a glowing symbol of uncertainty. The check engine light, a cryptic messenger, signals a host of potential issues, including the unraveling of the CP4 pump’s integrity. The vehicle’s diagnostic codes must be unveiled, offering a glimpse into the root of this mechanical conundrum.

Metallic Contaminants

The orchestra of mechanics turns sinister as the CP4 pump’s internal components succumb to wear. Metallic contaminants, once dormant within the pump’s chambers, infiltrate the fuel system. This foreign intrusion spells potential disaster, casting a shadow over fuel purity and clogging filters.

Abnormal Noise

Listen closely, and the engine’s song has shifted. A dissonant melody of knocks and ticks emanates from the heart of the mechanical beast. These auditory revelations echo the internal turmoil of the CP4 pump, where structural integrity battles the specter of impending failure.

Complete Engine Failure

In the most dire of scenarios, the CP4 pump’s final curtain call arrives. Its last act involves unleashing a torrent of metallic debris into the engine’s veins. The consequence is a symphony of destruction—a catastrophic failure that necessitates a mournful retreat to the repair shop, with a heavy price tag in tow.

Common Causes of CP4 Pump Failure

Understanding the potential causes of CP4 pump failure can help vehicle owners take preventive measures:

| Issue | Description |

|---|---|

| Fuel Contamination | Poor-quality or contaminated diesel fuel stands as a prominent adversary to the CP4 pump’s longevity and functionality. The internal mechanisms of the CP4 pump can suffer accelerated degradation when exposed to fuel containing impurities. Contaminants such as water, debris, and sediments present in the fuel can act as abrasive agents, gradually eroding the pump’s critical components. This emphasizes the significance of using clean and high-quality diesel fuel to ensure the pump’s optimal performance. |

| Lubrication Issues | In a paradoxical twist, the CP4 pump relies on the diesel fuel itself for lubrication. This intricate design necessitates the presence of adequately lubricating fuel to ensure the pump’s smooth operation. However, when the engine runs on low fuel levels, or if subpar fuel with inadequate lubricating properties is used, the CP4 pump faces the peril of insufficient lubrication. This, in turn, leads to premature wear and tear of the pump’s components, potentially culminating in failure. |

| Excessive Heat | The CP4 pump operates under demanding conditions, especially in scenarios involving heavy towing or sustained strenuous driving. These conditions generate elevated operating temperatures that can push the pump beyond its heat tolerance limits. Excessive heat exposure compromises the structural integrity of the pump, accelerating its wear and increasing the likelihood of failure. Thus, conscientious driving practices, coupled with appropriate cooling measures, become pivotal in extending the CP4 pump’s lifespan. |

| Lack of Maintenance | The adage “out of sight, out of mind” should not apply to CP4 pump maintenance. Neglecting routine upkeep tasks poses a significant risk to the pump’s health. Regular maintenance practices such as periodic fuel filter changes and comprehensive fuel system inspections are indispensable. Over time, contaminants can accumulate within the fuel system, infiltrating the CP4 pump and causing insidious damage. By adhering to a diligent maintenance schedule, vehicle owners can nip such issues in the bud and extend the CP4 pump’s operational longevity. |

Conclusion

The CP4 fuel injection pump plays a critical role in the performance and reliability of the 6.7 Powerstroke engine. Recognizing the symptoms of a failing CP4 pump and understanding its potential causes can help diesel vehicle owners take proactive steps to prevent costly engine damage. Regular maintenance, fuel quality awareness, and the use of additional filtration systems can contribute to a longer-lasting and trouble-free CP4 pump and engine operation. If you suspect CP4 pump issues, consulting with a professional mechanic and addressing the problem promptly is the best course of action to keep your diesel engine running smoothly.

FAQ

While complete prevention is challenging, maintaining a regular maintenance schedule, using high-quality fuel, and installing additional fuel filtration systems can significantly reduce the risk of CP4 pump failure.

The cost of replacing a CP4 pump can vary based on factors such as labor rates and whether you choose an OEM or aftermarket replacement. Generally, it can range from several hundred to over a thousand dollars.

Yes, some aftermarket companies offer CP4 pump upgrade kits designed to address the inherent flaws of the original pump design and improve its reliability.

It’s not recommended. Continuing to drive with a failing CP4 pump can lead to further damage to the engine and other components, potentially resulting in more extensive and costly repairs.

It’s recommended to follow your vehicle manufacturer’s guidelines. However, changing fuel filters every 10,000 to 15,000 miles is a common recommendation to maintain fuel system health.